Fasteners play a crucial role in various industries, from construction and manufacturing to aerospace and automotive. With a vast array of fasteners available, it can be overwhelming to choose the right one for your specific needs. In this article, we'll delve into the world of universal fasteners, exploring the five essential types that are widely used across different sectors.

Fasteners are used to join or hold objects together, and their applications are diverse. From simple tasks like assembling furniture to complex projects like building aircraft, fasteners are an essential component. Universal fasteners, in particular, are designed to be versatile and adaptable, making them suitable for a wide range of applications.

The Importance of Choosing the Right Fastener

Choosing the right fastener can be a daunting task, especially with so many options available. The wrong fastener can compromise the structural integrity of a project, lead to safety hazards, or even cause costly delays. On the other hand, selecting the right fastener can ensure a strong and reliable bond, reduce maintenance needs, and improve overall efficiency.

5 Essential Types of Universal Fasteners

In this section, we'll explore the five essential types of universal fasteners that are widely used across different industries.

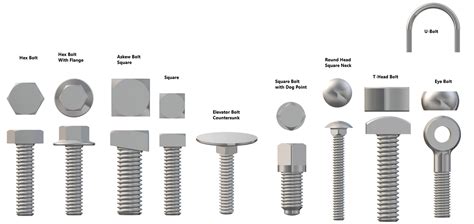

1. Bolts

Bolts are one of the most common types of fasteners used in various industries. They consist of a threaded shaft with a nut or bolt head on one end. Bolts are used to join two or more objects together, providing a strong and secure bond.

2. Nuts

Nuts are an essential component of the fastening system, used in conjunction with bolts to secure objects together. They are available in various shapes and sizes, including hexagonal, square, and wing nuts.

3. Screws

Screws are another type of universal fastener, used to join objects together by threading into a pre-drilled hole. They are available in various types, including wood screws, machine screws, and self-tapping screws.

4. Rivets

Rivets are a type of fastener used to join two or more objects together by inserting a rivet through a pre-drilled hole and then deforming the tail to secure it in place.

5. Washers

Washers are a type of fastener used to distribute the load of a bolt or screw, preventing damage to the surrounding material. They are available in various types, including plain washers, lock washers, and spring washers.

Benefits of Using Universal Fasteners

Universal fasteners offer several benefits, including:

- Versatility: Universal fasteners can be used in a wide range of applications, making them a convenient choice for various projects.

- Ease of use: Universal fasteners are often easy to install and require minimal specialized tools.

- Cost-effectiveness: Universal fasteners are often less expensive than specialized fasteners, making them a cost-effective choice.

- Reliability: Universal fasteners are designed to provide a strong and reliable bond, reducing the risk of failure.

Conclusion

In conclusion, the five essential types of universal fasteners – bolts, nuts, screws, rivets, and washers – are widely used across different industries. These fasteners offer versatility, ease of use, cost-effectiveness, and reliability, making them a convenient choice for various projects. By choosing the right fastener for your specific needs, you can ensure a strong and secure bond, reduce maintenance needs, and improve overall efficiency.

What are the benefits of using universal fasteners?

+Universal fasteners offer several benefits, including versatility, ease of use, cost-effectiveness, and reliability.

What are the different types of universal fasteners?

+The five essential types of universal fasteners are bolts, nuts, screws, rivets, and washers.

How do I choose the right fastener for my project?

+Choose a fastener that matches the requirements of your project, considering factors such as material, size, and load capacity.