A universal joint shaft is a type of mechanical component used to connect two rotating shafts that are not in the same plane. It is designed to transmit rotational motion and power from one shaft to another while accommodating the misalignment between the two shafts. This component is widely used in various industries, including automotive, aerospace, industrial machinery, and more.

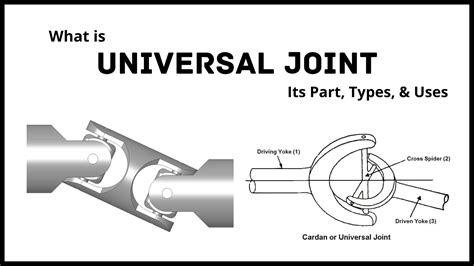

The universal joint shaft consists of two yokes, a cross, and four bearings. The yokes are attached to the ends of the two shafts, and the cross is the central component that connects the two yokes. The bearings allow for smooth rotation of the joint, even when the shafts are misaligned. This design enables the universal joint shaft to handle high torque and speed while maintaining a high level of precision and reliability.

History of Universal Joint Shafts

The concept of universal joint shafts dates back to the early 20th century, when they were first used in the automotive industry. The first universal joint was invented by French engineer Alfred Vischer in 1902. Vischer's design used a cross-shaped joint with four bearings to connect two shafts. This design became the standard for universal joint shafts and has been widely used ever since.

Types of Universal Joint Shafts

There are several types of universal joint shafts, each designed for specific applications and industries. Some of the most common types include:

- Cardan Joint Shaft: This type of universal joint shaft is used in applications where high torque and speed are required. It is commonly used in automotive and aerospace industries.

- Hooke's Joint Shaft: This type of universal joint shaft is used in applications where high precision and reliability are required. It is commonly used in industrial machinery and robotics.

- Double Cardan Joint Shaft: This type of universal joint shaft is used in applications where high torque and speed are required, and the shafts are subject to high misalignment.

Applications of Universal Joint Shafts

Universal joint shafts have a wide range of applications in various industries. Some of the most common applications include:

- Automotive Industry: Universal joint shafts are used in drivetrain systems to connect the engine to the transmission and differential.

- Aerospace Industry: Universal joint shafts are used in aircraft and spacecraft to connect engines to propellers and gearboxes.

- Industrial Machinery: Universal joint shafts are used in industrial machinery such as pumps, generators, and gearboxes.

- Robotics: Universal joint shafts are used in robotic arms and grippers to provide precise and reliable motion.

Benefits of Universal Joint Shafts

Universal joint shafts offer several benefits, including:

- High Precision: Universal joint shafts provide high precision and reliability, making them suitable for applications where accuracy is critical.

- High Torque and Speed: Universal joint shafts can handle high torque and speed, making them suitable for applications where high power is required.

- Flexibility: Universal joint shafts can accommodate misalignment between shafts, making them suitable for applications where flexibility is required.

Conclusion

In conclusion, universal joint shafts are an essential component in various industries, providing high precision, reliability, and flexibility. With their wide range of applications and benefits, universal joint shafts continue to play a critical role in modern technology.

What is a universal joint shaft?

+A universal joint shaft is a type of mechanical component used to connect two rotating shafts that are not in the same plane.

What are the benefits of universal joint shafts?

+Universal joint shafts offer high precision, reliability, and flexibility, making them suitable for a wide range of applications.

What are the common types of universal joint shafts?

+There are several types of universal joint shafts, including Cardan joint shafts, Hooke's joint shafts, and double Cardan joint shafts.