The Universal M25 thread standard has revolutionized the world of fine threads, offering a globally accepted and versatile solution for various industries. In this article, we will delve into the importance of fine threads, the features and benefits of the Universal M25 standard, and its applications across different sectors.

Fine threads have become an essential component in modern manufacturing, enabling the creation of complex and precise components. The need for a universal standard for fine threads has been growing, driven by the increasing demand for miniaturization and precision in various industries. The Universal M25 standard has emerged as the global benchmark for fine threads, providing a reliable and consistent solution for manufacturers and engineers worldwide.

The Evolution of Fine Threads

Fine threads have undergone significant transformations over the years, driven by advances in technology and the need for miniaturization. The first fine threads were developed in the early 20th century, primarily for use in the aerospace and defense industries. These early fine threads were often custom-made, leading to compatibility issues and inconsistencies.

In the 1960s and 1970s, the development of standardized fine threads began, with organizations such as the International Organization for Standardization (ISO) and the American Society of Mechanical Engineers (ASME) playing a crucial role. However, these early standards had limitations, and the need for a more comprehensive and versatile standard became apparent.

The Universal M25 Standard

The Universal M25 standard was developed to address the need for a global standard for fine threads. This standard provides a comprehensive framework for the design, manufacture, and use of fine threads, ensuring consistency and compatibility across different industries and applications.

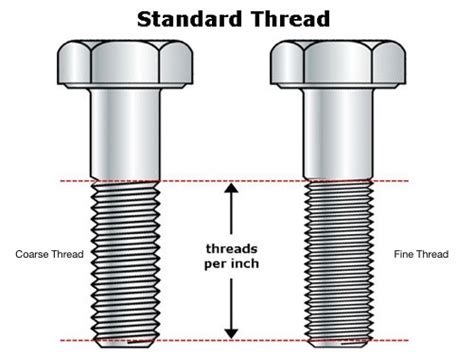

The Universal M25 standard is characterized by its unique thread profile, which features a 25° thread angle and a 0.5 mm pitch. This design provides a high level of precision and allows for the creation of complex components with ease.

Benefits of the Universal M25 Standard

The Universal M25 standard offers numerous benefits, including:

- Global compatibility: The Universal M25 standard is recognized and accepted globally, making it an ideal choice for international collaborations and supply chains.

- Precision and accuracy: The unique thread profile of the Universal M25 standard ensures high precision and accuracy, enabling the creation of complex components with ease.

- Versatility: The Universal M25 standard can be used across various industries, including aerospace, automotive, medical devices, and consumer electronics.

- Cost-effectiveness: The Universal M25 standard reduces the need for custom-made fine threads, resulting in cost savings and improved efficiency.

Applications of the Universal M25 Standard

The Universal M25 standard has a wide range of applications across various industries, including:

- Aerospace: The Universal M25 standard is used in the aerospace industry for the manufacture of aircraft and spacecraft components, where precision and accuracy are critical.

- Automotive: The Universal M25 standard is used in the automotive industry for the manufacture of engine components, transmission systems, and other precision parts.

- Medical devices: The Universal M25 standard is used in the medical device industry for the manufacture of implants, surgical instruments, and other precision components.

- Consumer electronics: The Universal M25 standard is used in the consumer electronics industry for the manufacture of smartphones, laptops, and other electronic devices.

Implementing the Universal M25 Standard

Implementing the Universal M25 standard requires careful planning and consideration. Here are some steps to follow:

- Assess your needs: Evaluate your current fine thread requirements and determine whether the Universal M25 standard meets your needs.

- Update your designs: Update your designs to incorporate the Universal M25 standard, ensuring compatibility and consistency.

- Train your staff: Provide training to your staff on the Universal M25 standard, ensuring they understand its features and benefits.

- Source compatible materials: Source materials that meet the Universal M25 standard, ensuring consistency and quality.

Gallery of Universal M25 Threads

FAQs

What is the Universal M25 standard?

+The Universal M25 standard is a global standard for fine threads, characterized by a unique thread profile with a 25° thread angle and a 0.5 mm pitch.

What are the benefits of the Universal M25 standard?

+The Universal M25 standard offers numerous benefits, including global compatibility, precision and accuracy, versatility, and cost-effectiveness.

How do I implement the Universal M25 standard?

+Implementing the Universal M25 standard requires careful planning and consideration, including assessing your needs, updating your designs, training your staff, and sourcing compatible materials.

In conclusion, the Universal M25 standard is a game-changer for the world of fine threads, offering a globally accepted and versatile solution for various industries. By understanding the features and benefits of this standard, manufacturers and engineers can create complex and precise components with ease, driving innovation and growth in their respective fields.